Inside Our Atelier

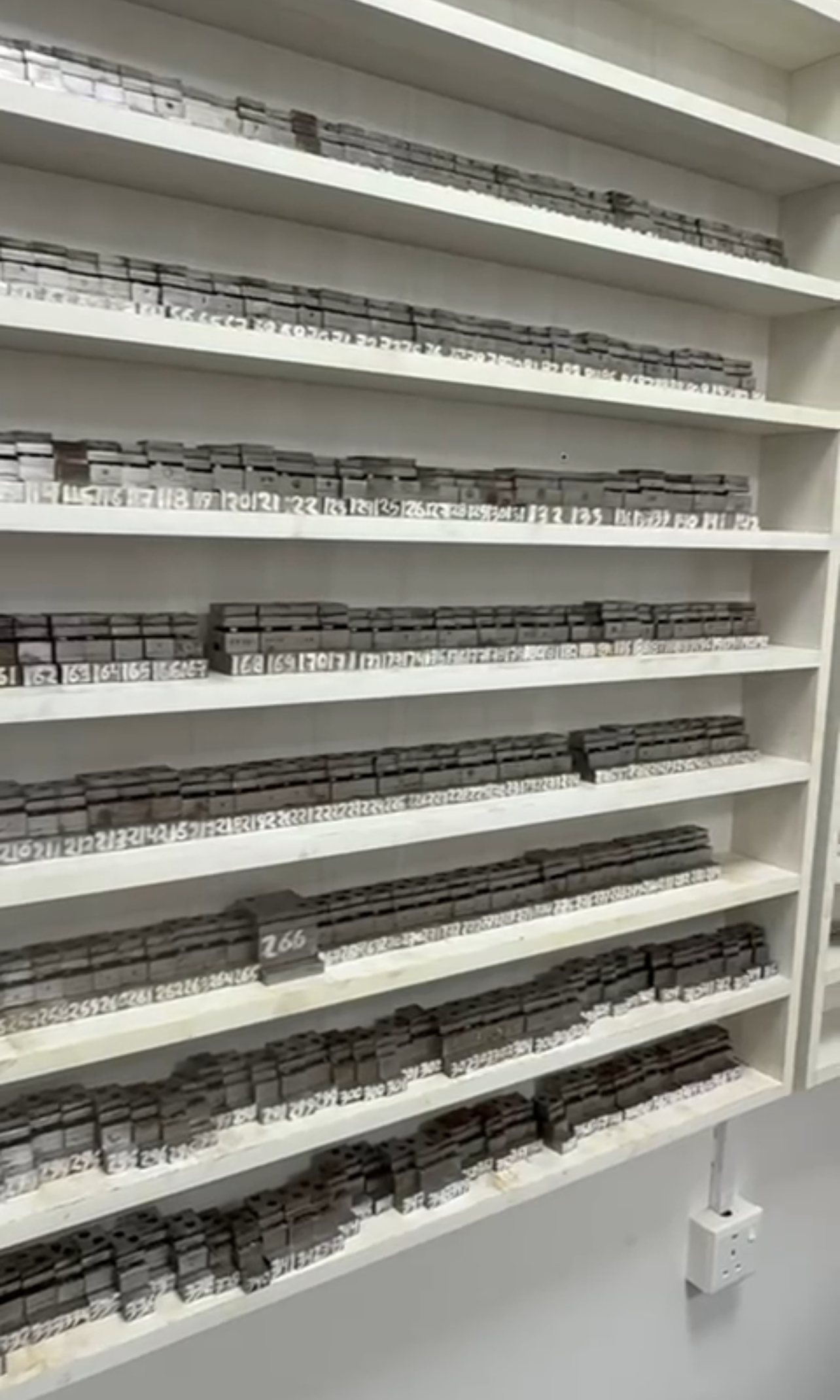

Each with decades of experience—master goldsmiths, handcrafted jewelry artisans, engravers, and polishers—all dedicated to perfection.

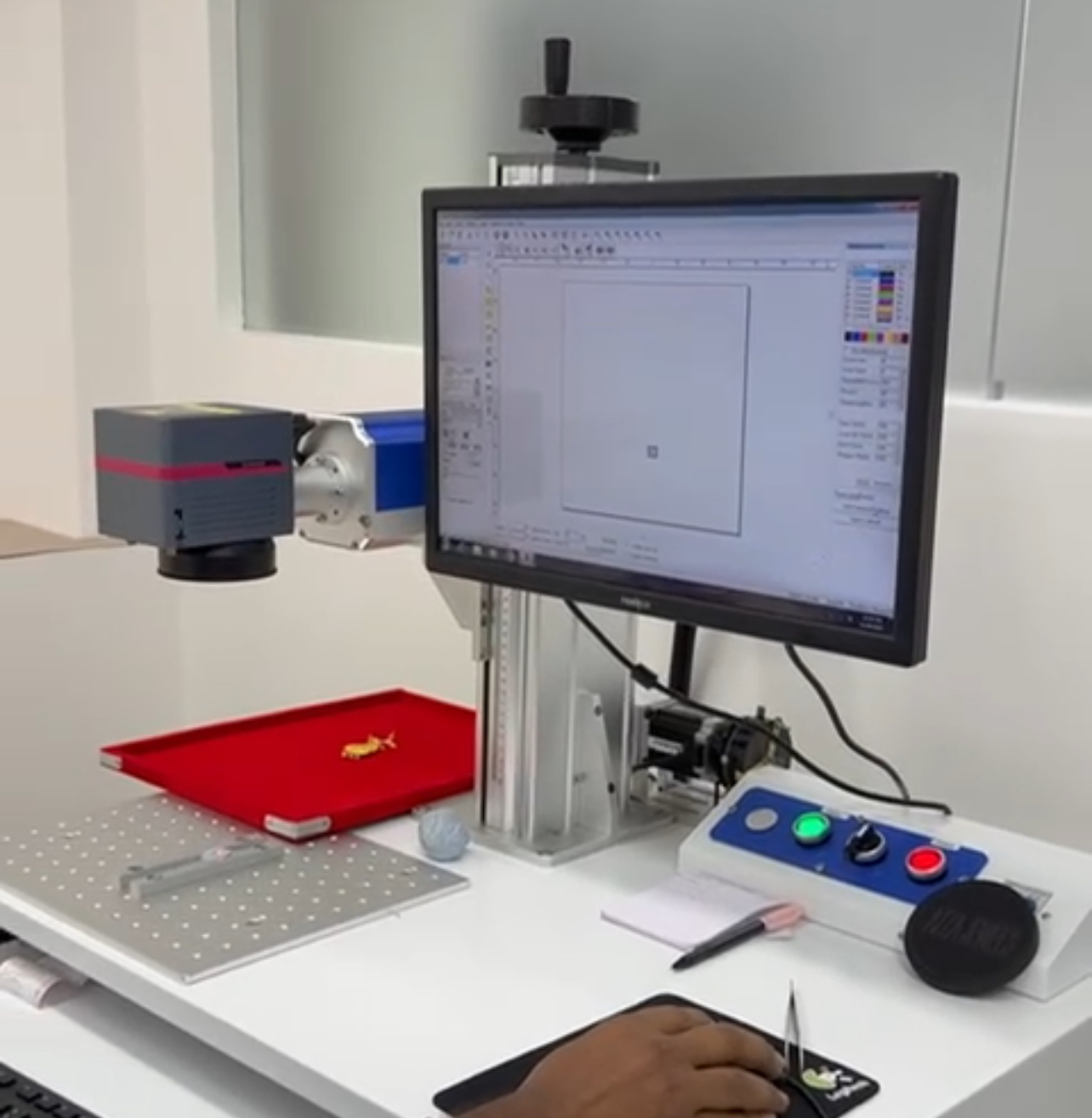

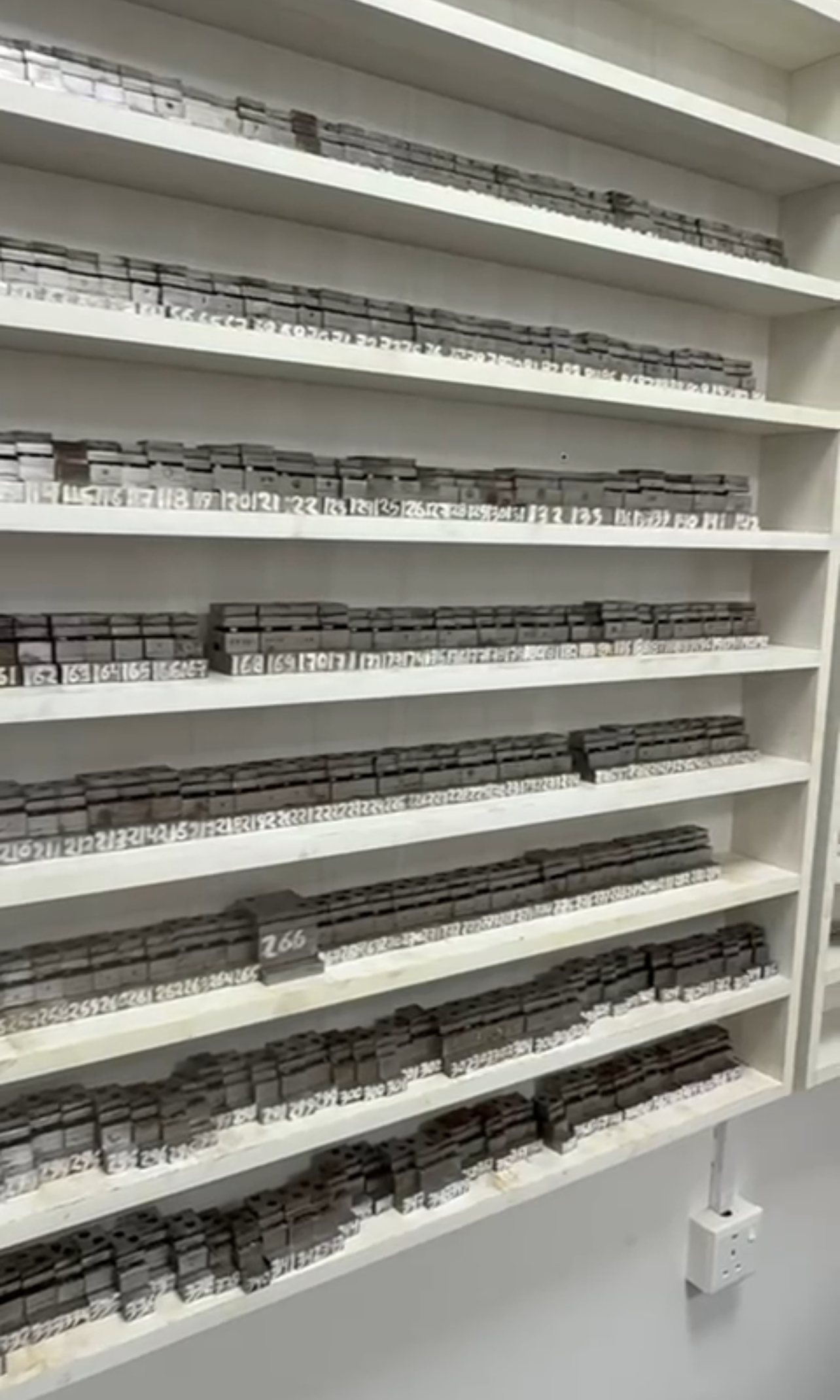

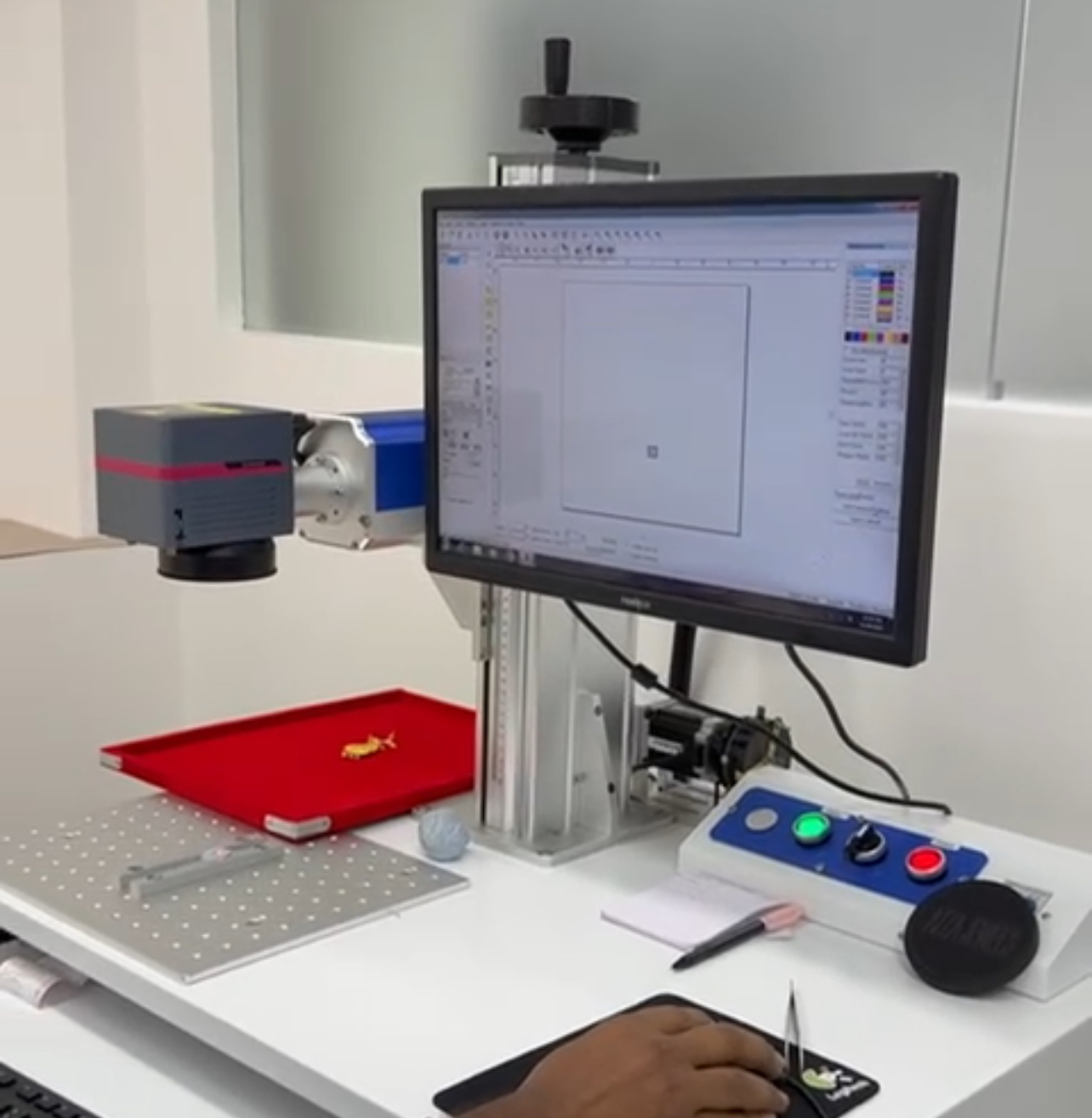

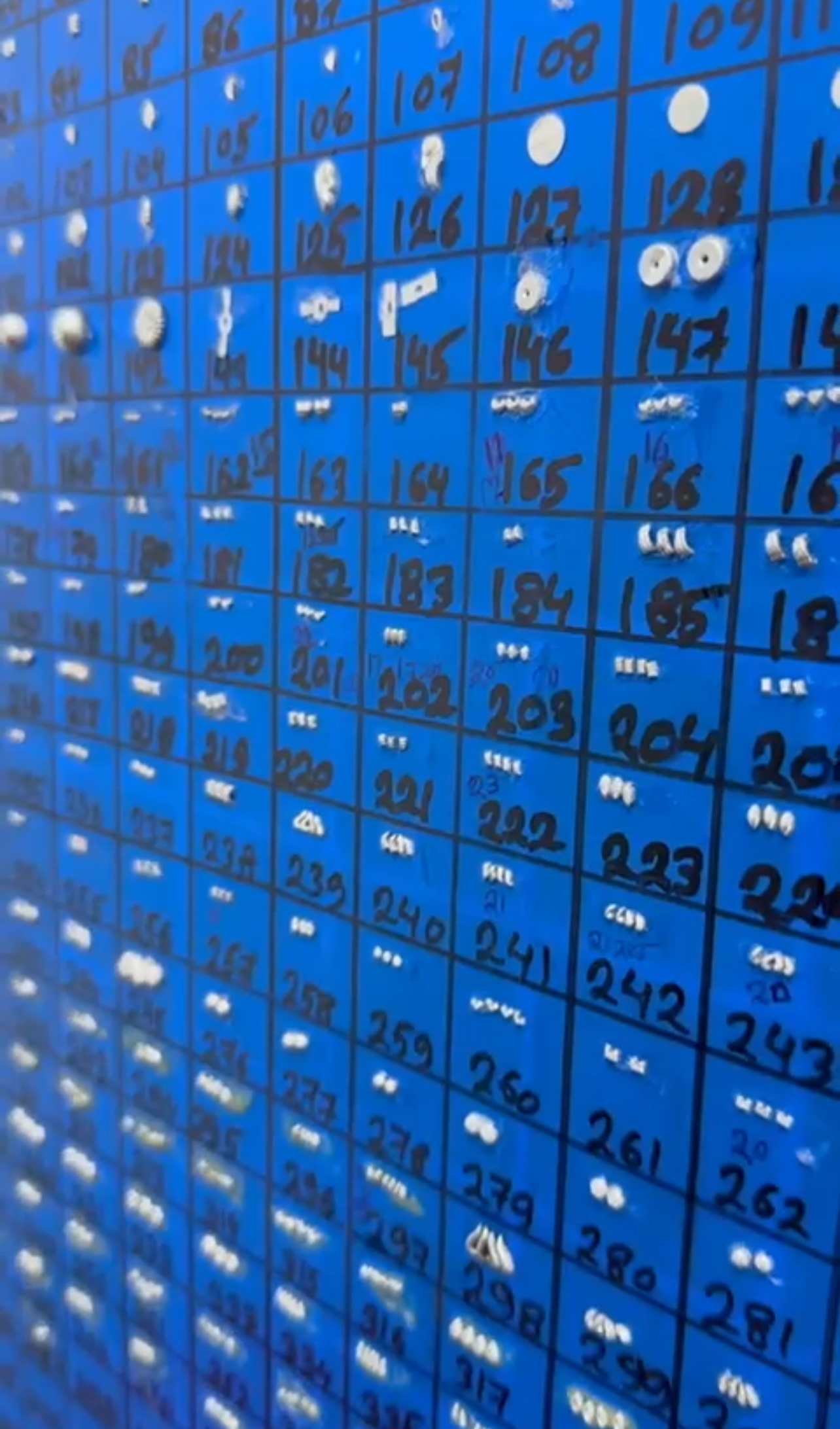

Equipped with both traditional benches and CNC-aided workstations, blending heritage techniques with modern precision.

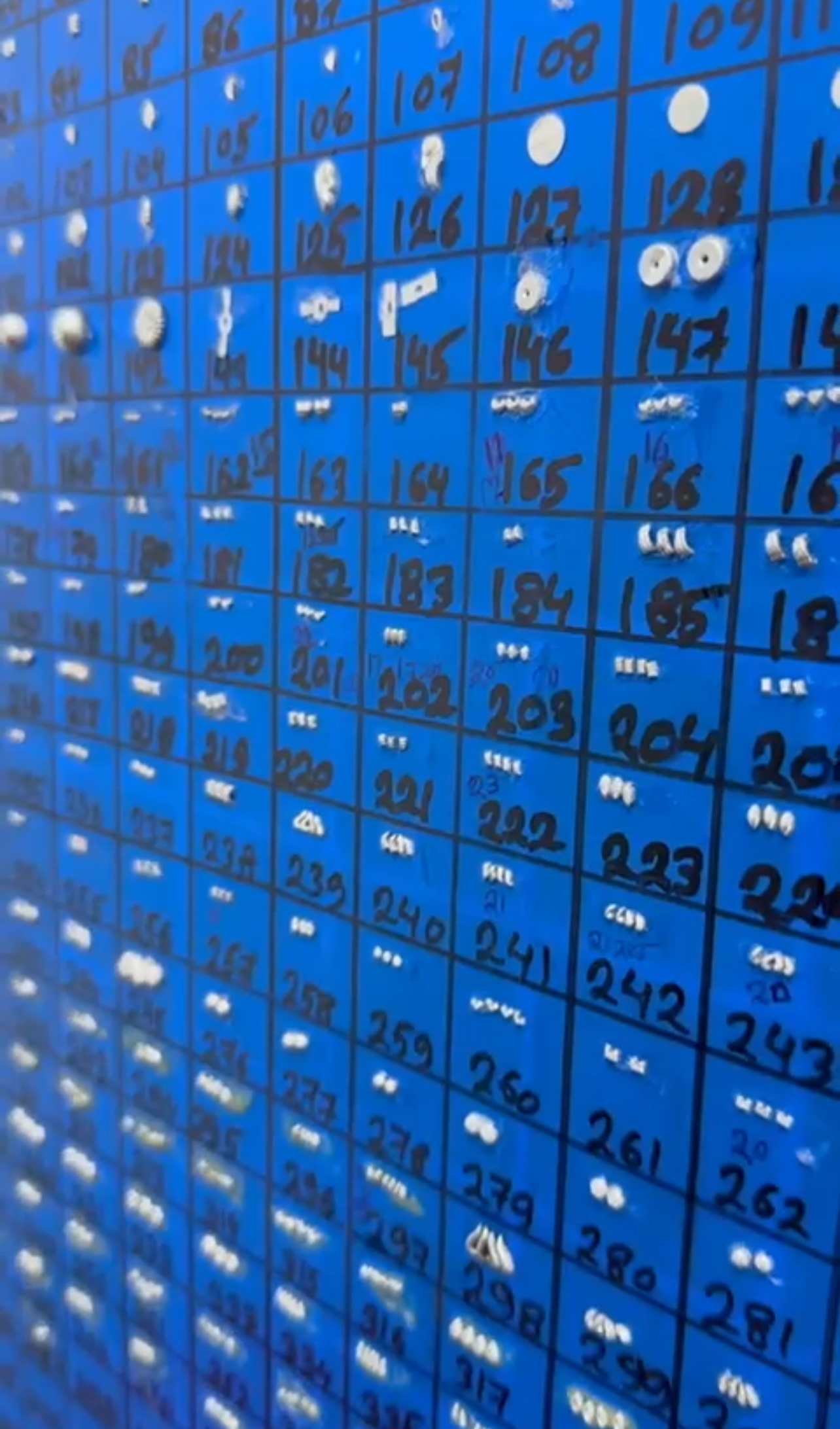

Dedicated prototyping lab for future collections, rapid iteration, and material testing in one premise—supported by ongoing research to meet and exceed international standards.

Every pure-gold piece undergoes a five-point QC check: assay & purity testing, official hallmarking, weight & dimension verification, alloy hardness testing, and surface-finish inspection.